2020年10月30日星期五

2020年10月29日星期四

Vacuum frying machine price

Stainless Steel Thermal Oil Vacuum Fried Fruit Chips Equipment

- Brief introduction of the Vacuum Potato Chips Frying Machine

What is a vacuum fryer or vacuum frying machine? How come this is considered as a healthier option when frying food? Technically, this is a device which is primarily used for deep-frying food. The frying occurs inside a chamber which reduces the amount of oil that is absorbed by food. Hence, it considered as a healthier alternative to common fryers. Originally, this was meant to deep-fry potatoes, though today, it has been widely used for commercial purposes in frying various types of food such as fruits chips and vegetable chips.

- Features of Mushrooms Vacuum Frying Machine

Maintaining the original color, flavor and nutrition of fruits & vegetables.

Crispness, no grease, is the favorite food of the young and old.

High fiber, multifold vitamins.

Having a good structure for quick rehydration.

Free preservatives, artificial color and flavour.

Convenient food, long shelf life (twelve months).

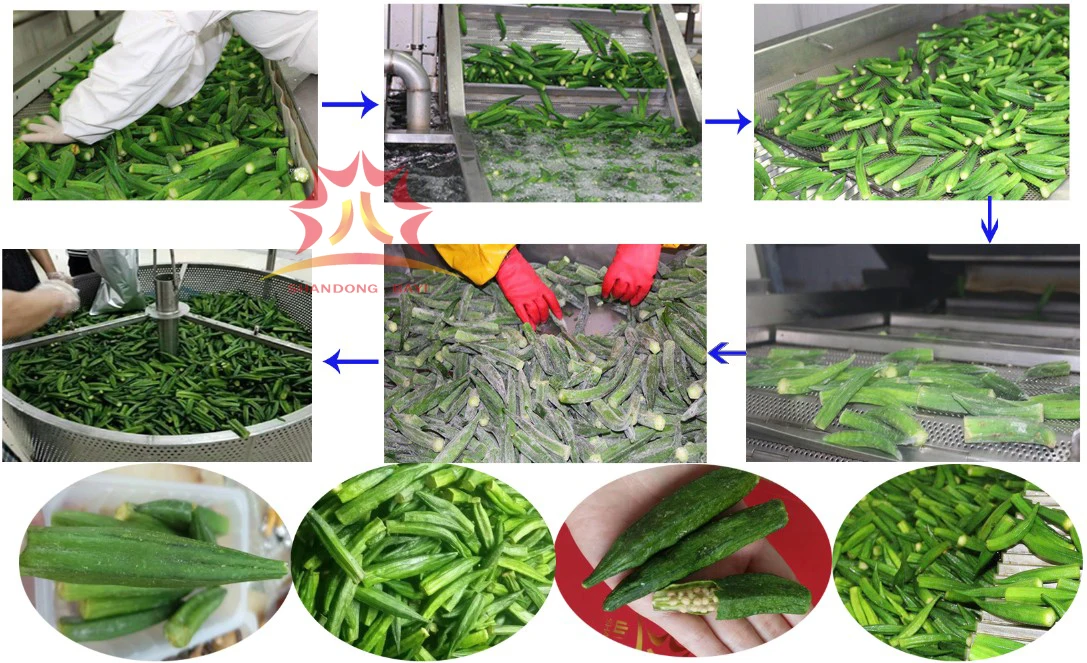

- Raw materials can be dealt by Apple Chips Vacuum Frying Machine

Most of fruit and vegetables which are very easy to be obtained and have attractive color, special flavor, more nutrition and low cost are much preferred to produce the crisp chips. Especially raw materials which can’t be processed by traditional frying method, as pineapple, strawberry, cucumber etc.

Raw materials used in common are as followed:

Fruits: Jackfruit, Apple, Pear, Persimmon, Banana, Pineapple, Peach, Mango, Strawberry, Chinese gooseberry, Carambola (star fruit), Muskmelon etc.

Vegetables: Onion, Carrot, Sweet potato, Potato, Pumpkin, Okra, Balsam pear, Taro, Lotus root, Kidney bean, Mushroom, Cucumber, etc.

Nuts: Peanut, Almond, Pea, Walnut, cashew nut etc.

Aquatic products: Fish, Shrimp, Shellfish, etc.

Others: Bean Product, meat, Chinese herbal medicine, etc.

Additional materials:

Frying oil, Palm oil, Refined vegetable oil.

Assistant: Sugar, Maltose, Salt, Natural flavoring, etc.

- Operation instruction of the Pawpaw Chips Vacuum Fryer

Thermal oil, boiler or electric heat Use to heater cooking oil . There Temperature is automatic controller for different products . We set up before .

Raw material feed into baskets

Fully automatic Pneumatic door opening and then baskets are fed in the chamber of the vacuum cooking chamber.

That time baskets lift into above heater cooking oil ( no contact in cooking oil ) . When vacuum about 720 – 760 mmHg and Temperature enough are baskets to dip in hot cooking oil .

Baskets will lift above heater cooking oil When setting timer is enough .The vacuum will disappear when the door opens again.

Oil in the raw materials will be get out by centrifugal force.

Technical parameter of Fruit Chips vacuum Frying Machine

Model | BYZK-500 | BYZK-800 | BYZK-1200 |

Size(mm) | 5600x2200x3600mm | 5600x2200x3600mm | 6200x2500x3600mm |

Basket size(mm) | Φ500x400mm | Φ800x400mm | Φ1200x400mm |

Basket volume | 80L | 200L | 400L |

Basket number(pcs) | 1 | 1 | 1 |

Heating method | steam/thermal oil/electricity | steam/thermal oil/electricity | steam/thermal oil/electricity |

Machine power(kw) | 20/20/60KW | 24/24/100KW | 33/33/160KW |

Vacuum degree | -0.095~-0.100 | -0.095~-0.100 | -0.095~-0.100 |

Frying time | 50~120min | 50~120min | 50~120min |

Frying temperature | 80~110℃ | 80~110℃ | 80~110℃ |

Oil volume | 350KG | 500KG | 900KG |

Input capacity/batch | 50KG

| 100KG

| 150KG

|

Company Information of Shandong Bayi Food Industry Equipment Co.,Ltd.

Established in 2015, Shandong Bayi Food Industry Equipment Co.,Ltd. is located in Zhucheng, Weifang city with convenient transportation. The factory covers about 50,000 m2 with more than 70 working staff. We have our own research and development center. Main products of Bayi are Vacuum fryer, potato chips production line, French Fries process line, banana chips plant and other auxiliary equipment such as potato peeler, potato slicer, fruit drying oven, fruit and vegetable washing line and pasteurization line.

Certificate

After sales service:

We provide high quality service:

a) Consultation before, during, and after sales;

b) Project planning and design;

c) Debugging until everything is functional;

d) Shipping management from factory to the destination;

e) Installing, maintenance and operation training;

f) New production techniques and formulas;

g) 1 year complete warranty and life-time maintenance service.

Contact